The Tray Packer is a secondary packaging machine placed at the end of the chain for filling a packaging tray with fine-point ampoules output from a VACFILLER 100/200/300 production line.

It can then be connected to a boxing machine for packaging regular supplies.

With its simplicity of use and studied ergonomics, this semi-automatic machine fulfils its purpose while limiting unproductive time and avoiding a large amount of manual work.

Capacity

Up to 40,000 ampoules per running hour.

Customizable filling line

With four filler models and a wide range of complementary modules, each production line is precisely matched to the customer’s specific needs.

Small footprint

Ergonomic and compact, VACFILLER machines can easily be integrated into all types of laboratory.

Compliant with BPF and FDA specifications

The whole of the VACFILLER range complies with BPF (French good practice in manufacturing) and FDA requirements for pharmaceutical industry products and dietary complements.

What is the purpose of the Tray Packer ?

The tray packet performs the initial secondary packaging operation whereby the ampoules are inserted into cardboard trays in preparation for boxing.

This semi-automatic machine is compatible with and adaptable to various ampoule formats

It fits in easily at the end of the VACFILLER production line, just after the Dryer.

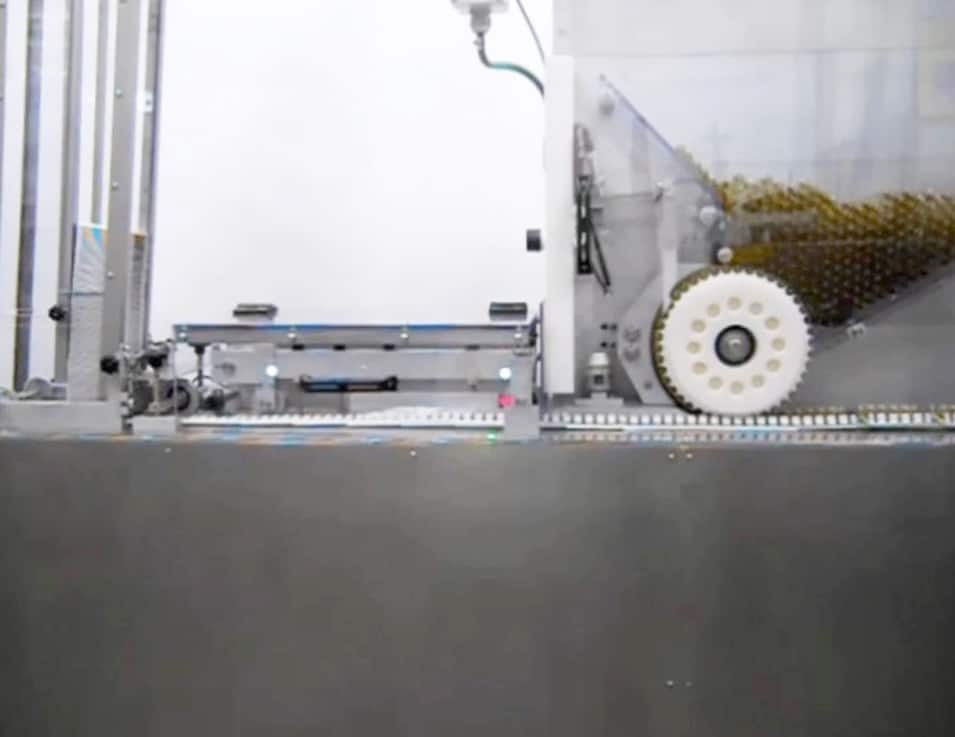

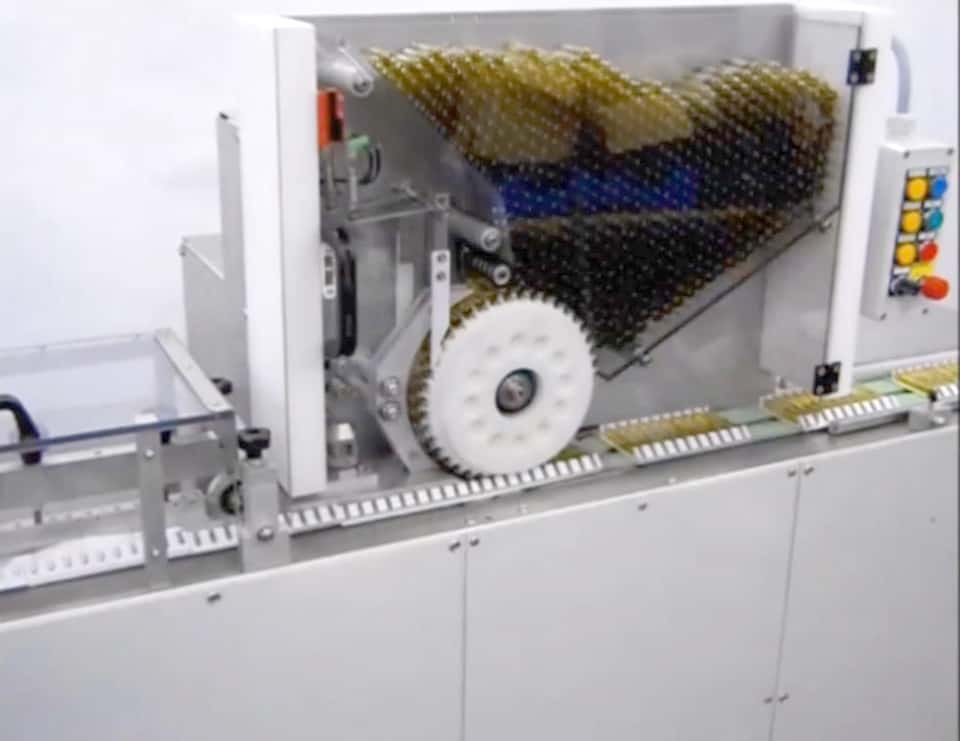

How does it work ?

The tray packer comes complete with the following devices:

An adjustable tray magazine

A forming/opening set adapted to the dimension of your trays

A hopper and an ampoule placing wheel to suit the dimensions of the ampoules and trays.

Designed for inserting fine-tip ampoules into their packaging trays without any fuss !

With its simplicity of use and studied ergonomics, the Tray Packer fills trays of ampoules in semi-automatic mode. It thus makes secondary packaging easier and saves time. This machine adapts to all ampoule and tray formats.

Intuitive operation with short learning curve.

- Machine with conveyor and variable speed drive ;

- Manual loading of ampoules and trays ;

- Automatically inserts the ampoules into the trays ;

- Quick changeover of format ;

- Complete tool kit for each ampoule format, limiting the adjustment.

Tough

- Stainless steel frame.

Installation prerequisites

- 380V 3-phase 50Hz ;

- Filtered compressed air at 6 bar if tray ejection option taken.

Optional extras

- Detection and warning of non-compliant ampoules ;

- Checking for ampoules present in tray ;

- Checking for unfilled ampoules in the tray ;

- Ejection of non-compliant trays ;

- Automatic loading of ampoules from crystallizing dishes on a conveyor ;

- Inkjet printing of batch number on tray.

A bespoke, upgradable production line with many advantages

The VACFILLER range can package ampoules from A to Z in record times. There are many advantages in all of the machines, not the least of which is a quick return on investment.

VACFILLER machines fill ampoules with extreme accuracy, guaranteeing reliability and quality.

Ergonomic and intuitive, VACFILLER machines have a short learning curve thanks to their simplicity of use.

VACFILLER modules are standard design machines. Maintenance is therefore performed using commonly available parts.

By filling their ampoules in-house, laboratories maintain full control over the packaging chain, especially on quality and lead-time.

Each model meets a well-defined requirement, ensuring perfect productivity, and accordingly a very short payback time.